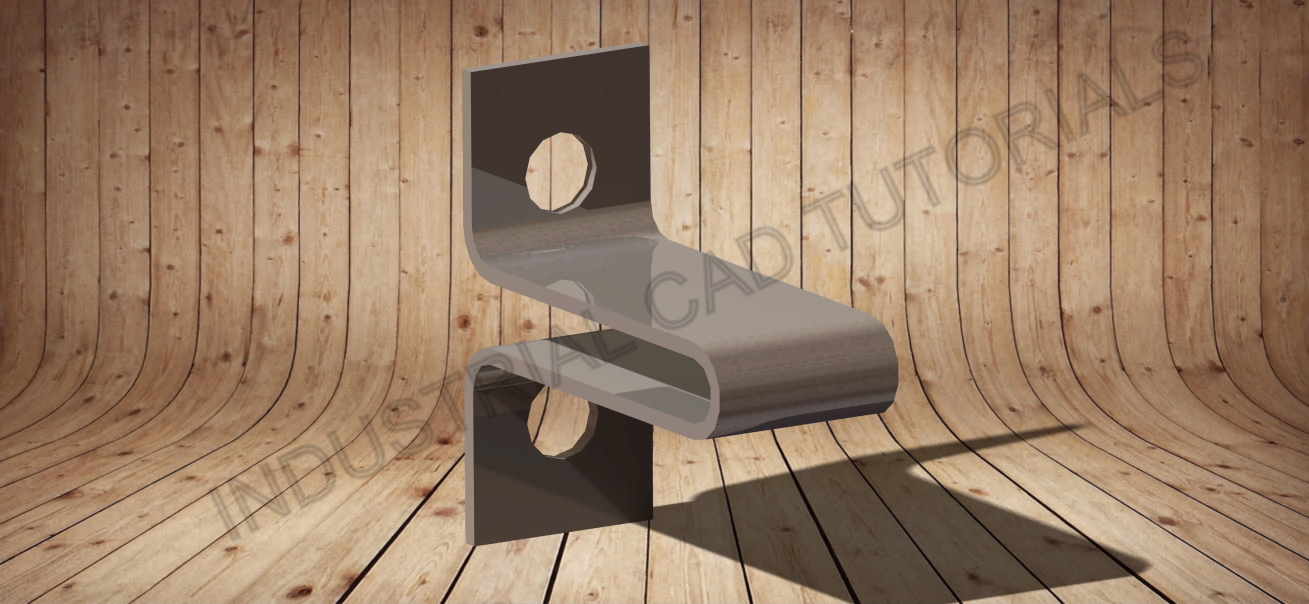

Developing lifting hooks in AutoCAD and CATIA involves creating detailed 2D and 3D representations of hooks used for lifting heavy loads in various industrial applications. Lifting hooks are essential components in material handling equipment, cranes, and rigging systems. They are designed to securely hold and lift objects while distributing the load evenly. AutoCAD and CATIA are powerful computer-aided design (CAD) software tools that can be used to create and model these lifting hooks.

Below are general steps for developing lifting hooks in both AutoCAD and CATIA:

1. Understand the Lifting Hook Requirements:

- Familiarize yourself with the specifications of the lifting hook, such as the load capacity, size, shape, and any specific safety standards or regulations to be followed.

2. AutoCAD:

- Start by creating a new drawing in AutoCAD.

- Use the 2D drafting tools to create a detailed plan view of the lifting hook.

- Draw the outline of the hook, considering the shape of the hook’s throat, the curve of the hook’s bend, and the dimensions of the hook’s tip.

- Add dimensions and annotations to specify critical details such as the hook’s dimensions and load capacity.

- If needed, create multiple views of the lifting hook to show it from different angles.

2. CATIA:

- Open CATIA and start a new Part Design or Generative Shape Design workbench, depending on the complexity of the lifting hook.

- Use sketches and 3D modeling tools to create the lifting hook’s 3D representation.

- Draw the outline of the hook, considering the shape of the hook’s throat, the curve of the hook’s bend, and the dimensions of the hook’s tip.

- Utilize features like extrusion and fillet to create the lifting hook’s overall shape and round the edges of the hook.

- Utilize CATIA’s advanced surfacing capabilities to create smooth and continuous surfaces for more complex lifting hook designs.

- Add dimensions and annotations to communicate critical information about the lifting hook.

3. Detailed Design (Optional):

- Add reinforcement features like ribs, gussets, or webbing to increase the lifting hook’s strength and rigidity.

- Consider adding any additional features required to improve the hook’s load distribution capabilities.

4. Analysis and Validation:

- If necessary, perform structural analysis or simulations on the lifting hook to ensure it meets the required load capacity and safety standards.

5. Documentation and Collaboration:

- Create detailed engineering drawings and documentation for manufacturing and assembly.

- Share the design files with relevant stakeholders, such as manufacturers or safety engineers, for feedback and collaboration.

Developing lifting hooks requires precision and adherence to safety standards to ensure they can safely handle the intended loads. Engineers with expertise in mechanical design and relevant industry standards should be involved in the process. Both AutoCAD and CATIA provide the necessary tools to create accurate and detailed lifting hook models, with CATIA being preferred for more complex designs due to its advanced 3D modeling capabilities.